Use of Rali handplanes

The handplanes are manufactured by stamping steel sheets. This stamping guarantees regularity in production and always exact dimensions.

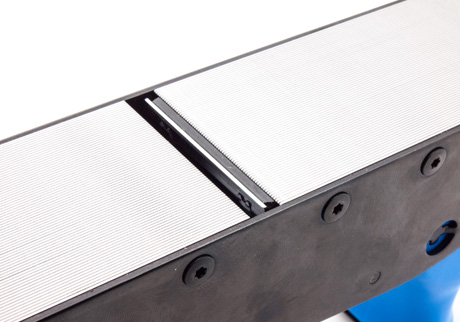

Blade always parallel

The parallelism of the blade is factory adjusted. As the knife is fixed on the blade holder, it cannot move, and therefore no looseness in the position. The blade holder is assembled on the handplane and spine around an eccentric. It can only be adjusted on the axis of the depth.

The parallelism of the blade is factory adjusted. As the knife is fixed on the blade holder, it cannot move, and therefore no looseness in the position. The blade holder is assembled on the handplane and spine around an eccentric. It can only be adjusted on the axis of the depth.

Cutting depth adjustment

The double-edged blade is fixed on the blade holder. The knife holder can be moved up and down with the red lever. The lever can be continuously adjusted to define the cutting depth.

Notamment:

- Lever to the top:

resting position with retracted blade. It is also the position on which the lever has to be placed to change the blade.

- Lever horizontally:

minimum wood gripping. Chip thickness: approx. 0.05mm. For handplanes with a heavy sole, it is recommended to set the back plate all the way forward.

- Lever to the bottom:

maximum wood gripping for roughing or chamfering. Chip thickness: approx. 0.5mm. For handplanes with a heavy sole, it is recommended to adjust the back plate all the way back.

Blade setting

The double-edged blade can be changed in few seconds.

It is available in two qualities: chrome steel or tungsten carbide, depending on the material to be planed :

- lift up the depth lever at the maximum

- unlock the blade holder by lifting the latch

- lift up the blade holder horizontally by pulling the depth lever

- open the blade holder by lifting the cap

- turn or change the knife

- gently pull down the cap on the blade holder

- reverse all the operations so that the handplane is ready for use

Back plate adjustment

On handplanes with a heavy sole, the back plate can be adjusted. To do that, you have to:

- lift up the depth lever at the maximum

- unlock the blade holder by lifting the latch

- raise the blade holder horizontally by pulling the depth lever

- roll the eccentric towards the blade to move the back plate forward

- roll the eccentric towards the back of the handplane to move the back plate backwards

- reverse all the operations so that the handplane is ready for use

Generally:

- Back plate backwards: roughing

- Back plate forward: finishing

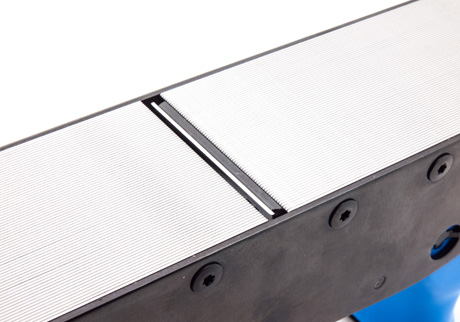

Throat opening adjustment

Depending on the species or if the timber is still live, the chip cannot pass in the gap between the blade and the front sole. In this case the handplane "is filled up" and the chips agglomeration has to be removed manually around the blade.

To avoid this, it is possible to open the throat opening on the 220 and 260 handplanes, as well as on the large rebate plane G30, d'by pulling the front sole plate few millimeters forward:

- take the key from the compartment provided (220 and 260: in the rear handle, G30 under the rear handle).

- unscrew the front sole plate screws on one side of the handplane by half turn

- push the front sole plate forward (few millimeters)

- tighten the screws and store the key.

ON Evolution RANGE: